Driving Sustainable Change: Insights from the ACT Major Projects Conference

At the recent ACT Major Projects Conference, representatives from TSA and The Footprint Company shared their innovative ideas and approaches for building a sustainable and resilient future. Dr Therese Flapper, General Manager of the Canberra Region at TSA, and Maddison Fisher, a dedicated member of The Footprint Company, delivered insightful presentations.

Meet the speakers

Dr Therese Flapper

Therese envisions city infrastructure as a means to serve humanity in a visionary, resilient, and commercially responsible manner. She emphasises the importance of taking timely steps to transform ambition, policies, and plans into sustainable and resilient built outcomes. Therese encourages the industry to expand its perspective beyond the conventional ‘time,’ ‘cost,’ and ‘quality’ triangle to incorporate ‘carbon’ and ‘community.’ Her insights highlight how the ACT can lead in transformative infrastructure.

Maddison Fisher

A member of The Footprint Company, Maddison tackled the pressing issue of embodied carbon in construction. She emphasised the critical role of the built environment in combatting climate change, particularly in reducing embodied carbon – a significant contributor to building-related emissions. Maddison’s presentation offered practical advice and strategies for fostering a more sustainable construction industry.

Therese’s Insights

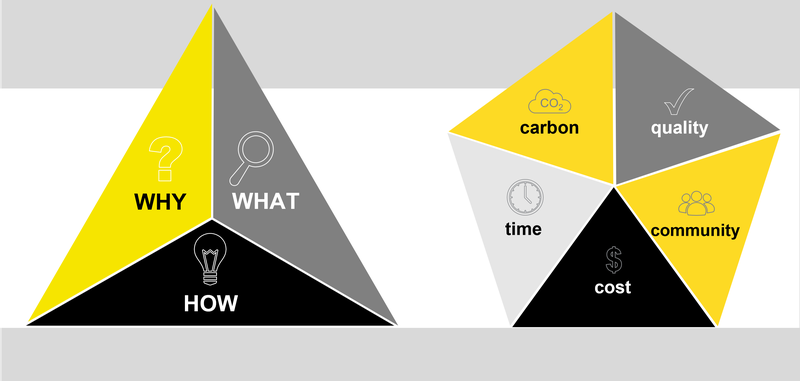

City Infrastructure needs to sit in the built environment in a way that serves humanity. It needs to be visionary, cognisant of a resilient future, and consider the whole of society (from the marginalised to the entrenched) while also being commercially responsible. We need to, therefore, explore how to take the right steps at the right time to transform ambition, policies and plans into sustainable and resilient built outcomes. The built environment has traditionally done this based on managing the triangular tensions across Time, Cost and Quality. To address both the current and future risks of the built environment, these tensions need to expand to consider Carbon and the Community. While a dozen parameters could be noted, Carbon and Community are foundational to exponentially driving step-change in the built environment. This shift in approach will generate change from planning, procurement, design, and delivery into long-term operations.

Many government agencies and private sector developers have numerous policies, strategies, and guidelines that delineate the “why” and “what” of their objectives within the built environment. However, finding tangible approaches of “how” to achieve this balance across Time, Cost, Quality, Carbon, and Community can be challenging.

Five proposed “how” elements are:

- Implement an ESG Framework – Introducing a formally externally assured framework will enhance cohesion and measured direction for any built environment setting. Aligning to initiatives such as the Global Reporting Initiative drives material impacts to be managed. We have developed and suggest running a robust ESG Verification Checklist on everything to be built.

- Portfolio or Program Led – Typically, the built environment tackles brownfield and greenfield developments one project at a time, gradually reshaping our landscape project by project. However, adopting precinct, portfolio, or program-led management shifts the discourse, presenting and representing risks and opportunities from a broader perspective – a better platform for considering Carbon and the Community.

- From Governance to Measure – Often, a formal governance arrangement of meetings and workshops will exist, sometimes including KPIs. It is less common to have a holistic governance framework that aligns with all policies, strategies and guidelines of the project being delivered on the ground. Maintaining a measured approach, which ensures alignment with the project’s strategy through checking, tracking, responding, and reacting, is more likely to drive positive environmental and social outcomes.

- Carbon must be measured – The tools and databases are readily available for routinely measuring embodied carbon in the built environment. While this may not be an exact science, it has evolved beyond the minimum viable product stage and should be integral to the design process. It is advisable to make measuring embodied carbon mandatory, starting from the planning phase through design development and project delivery. This approach aims to facilitate data-driven decision-making regarding the built form. Although many express a desire to reduce carbon, these tools are not as widely and robustly deployed as they could be. Hence, it’s essential to calculate and report embodied carbon every time you prepare a time and cost plan.

- Community must be defined and served – For most projects, we typically engage in formal stakeholder and community consultations. It’s also common practice to employ a human-centred design (or other) approach to consider how a built form will interact with people. Less common but notable is community-led place-making and precinct ownership; defining and designing for the array of communities to be served; and considering end-user profiles encompassing gender, individuals with disabilities, and other disadvantaged or marginalised groups.

Maddy’s Insights

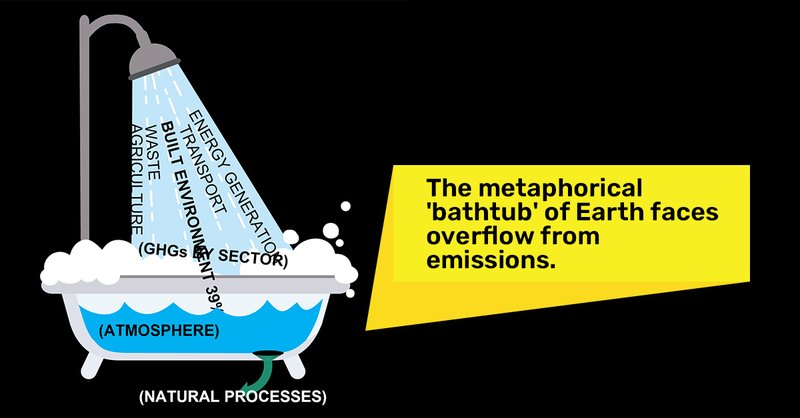

Carbon reduction is vital in construction. The Paris Agreement, signed by 196 countries in 2016, aims to cut emissions by 43% by 2030 and achieve net-zero emissions by 2050. The built environment contributes 39% of global greenhouse gases, with 28% from operational energy and 11% from construction materials.

Construction emissions fall into three categories: Scope 1 (direct operations), Scope 2 (indirect emissions), and Scope 3 (supply chain emissions, in the built environment is embodied carbon). By 2050, embodied carbon may make up 80% of built environment emissions.

The metaphorical ‘bathtub’ of Earth faces overflow from emissions. To tackle this, the construction industry needs a unified ‘language of carbon.’

Maddison offers 3 key steps for practically incorporating emissions reduction:

- Measure: To reduce carbon in construction, start by assessing your project’s typical carbon footprint. You can measure it at various stages, like financial reporting. Two data types are crucial:Topdown Data: Ideal for project initiation, giving a broad but cautious estimate of embodied carbon.Bottom-up Process Data: Used later when the project’s scope is clear. Typically, from Environmental Product Declarations (EPDs) by suppliers (it is detailed but may miss some aspects and can be costly).In the project’s midlife cycle, consider a combined approach (combination data) for a comprehensive evaluation. Carbon accounting services (e.g., The Footprint Company) and quantity surveyors can assist with this.

- Benchmark: Projects need benchmarks to set reduction targets. Currently, industry-average data is limited. NABERS is collaborating with the government to enhance benchmarking data consistency. Reliable industry benchmarks are available through established carbon accounting firms like the Footprint Company. It’s recommended to set quantitative reduction goals based on a percentage decrease from these benchmarks, aligning with project progress before aiming for a Paris Agreement reduction goal of 40%.

- Apply Reduction Considerations: These five carbon reduction considerations can be applied at any project stage, with varying impacts on embodied carbon reduction:

- Build Less: Reduce supply chain impact by building, buying, and designing less. This saves time and money.

- Reuse/Repurpose: Prioritise reuse and repurposing over new construction. Examples like the Mid-town Centre redevelopment in Brisbane demonstrate substantial savings in concrete and steel.

- Optimise/Dematerialise: Optimise systems and dematerialise designs when new construction is necessary. Efficient, lightweight, durable, and climate-adaptive design practices are crucial.

- Materials with Recycled Content: Select materials with recycled content to achieve emission reduction.

- Low Carbon Supply Chain: Choose materials with a low carbon supply chain for further emissions reduction.